HycoFusion®

HycoFusion® is as simple as it is ingenious! An aluminum, steel or plastic profile is firmly bonded to a wooden core without adhesive to form a high-performance hybrid material.

By combining the advantages of the respective material properties, application-optimized solutions can be developed that bring significant improvements in terms of ecology and technical performance. The lightweight material wood thus helps to save up to 50% of the original material content while maintaining the same performance.

HycoFusion® is suitable for load-bearing and highly stressed structures. It can be used to create rigid, strong, impact-resistant, lightweight, fire- and weather-resistant solutions in the construction sector, mechanical engineering, plant engineering and vehicle construction.

HycoFusion®makes a significant contribution to achieving eco-political goals such as Paris 2050:

Wood is an important, sustainable and, above all, renewable raw material.

One way to create a CO2 reduction is to increase the use of wood in a wide range of applications and thus replace other materials with a negative CO2 balance.

According to Hanewinkel, consistent implementation of this goal in the European economic area could save around 90 million tons of CO2 per year.

Source: Scottish Centre for Carbon Storage und Prof. Hanewinkel (Uni-Freiburg) (2012)

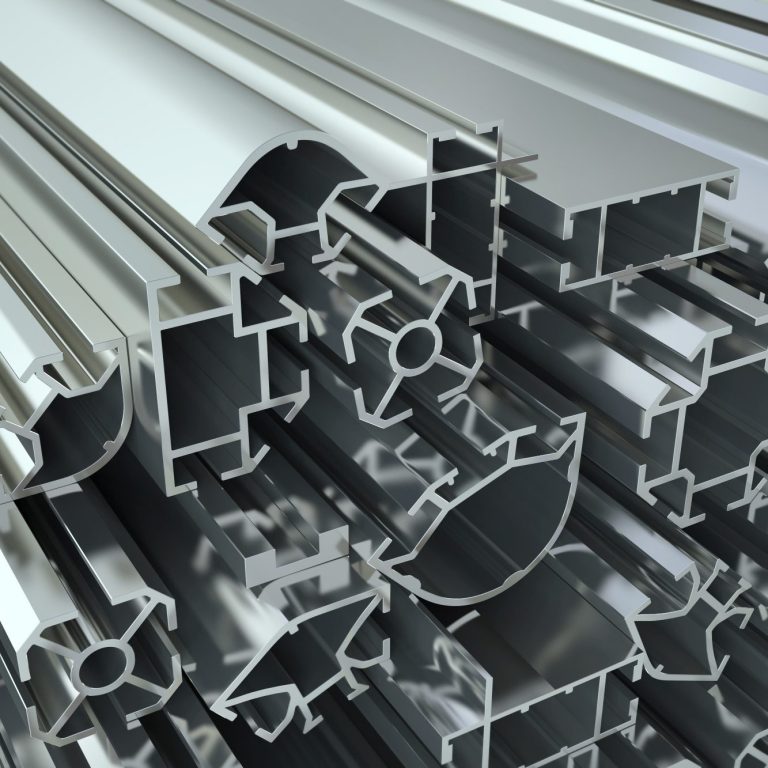

HycoFusion®alu

Aluminium

With a ratio of 1kg aluminum / 6kg CO2-equivalent, every kilogram of material saving counts on the way to achieving the targeted climate goals.

With EcoFusion®alu, at least 35% aluminum can be substituted by the ecological material wood while maintaining or even increasing technical performance.

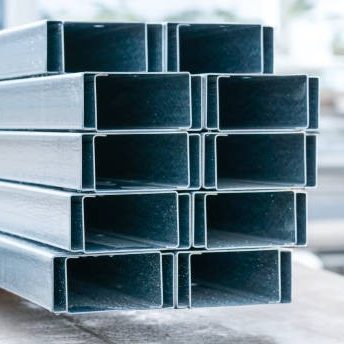

HycoFusion®steel

Steel

With a ratio of 1kg wood / 10kg steel, EcoFusion®steel can advance into lightweight construction applications that were previously reserved for light metals.

We combine the advantages of the bulk materials wood and steel and also save a lot of CO2.

HycoFusion®plastics

Plastics

With a ratio of around 1/3 of the mechanical properties of plastic to wood, EcoFusion®plastics enables a significantly wider range of applications for mechanically stressed plastic profiles in interior and exterior areas. Here we boost the properties of plastic and also save a lot of CO2.

Potential users of HycoFusion®

Aluminium profile producers

Steel profile producers

Plastic extruders

Window and facade systems

Wood building and engineering

Mobility and transportation

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.